Eco-egg: everything on one production site

Renewable electricity generation

1300m2 of photovoltaic panels are installed on our buildings. The annual production of about 180 megawatts easily covers all our electrical energy needs.

The entire site is heated with heat pumps, powered by renewable energy.

A wood-burning boiler ensures the temperature of the chicks’ ambient air.

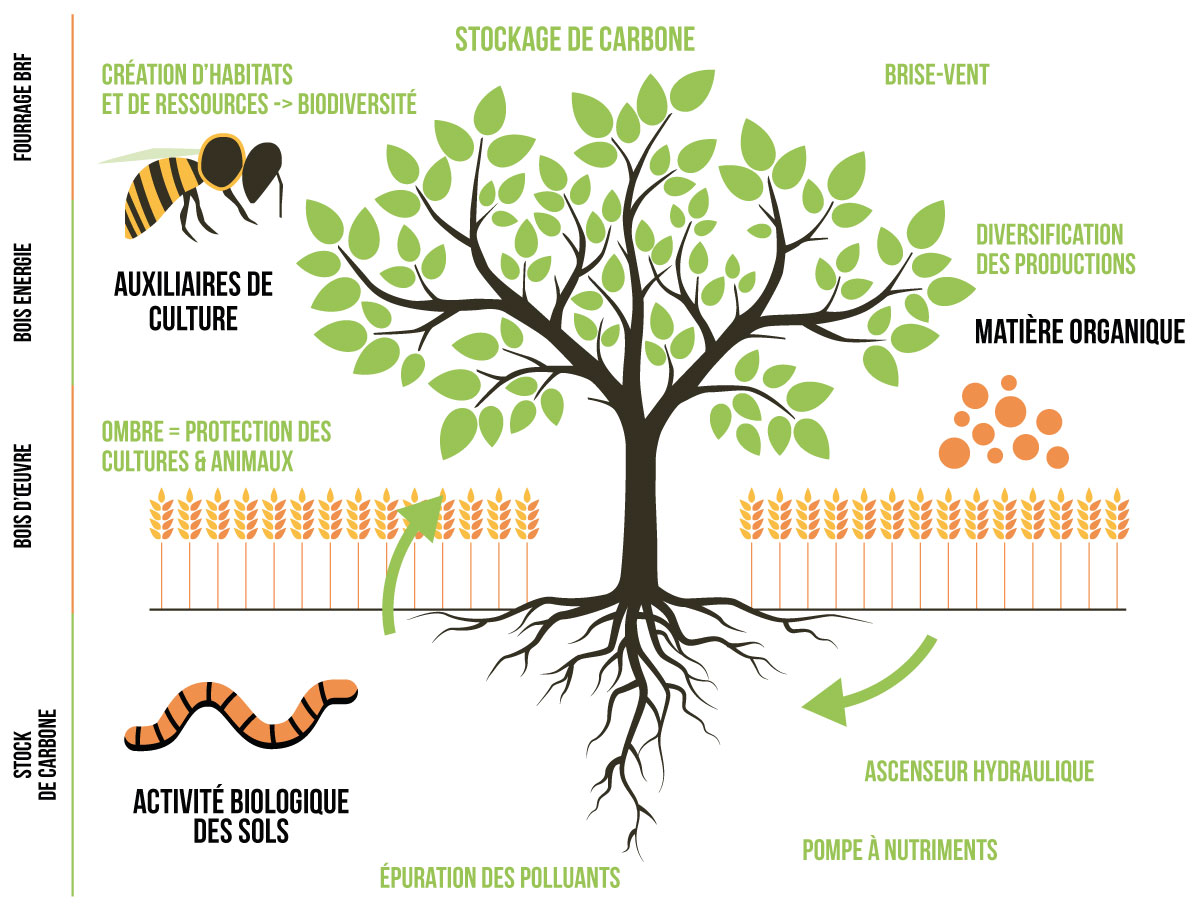

Agroecology and agroforestry

Biodiversity helps to limit or eliminate the use of plant protection products. For this reason, our PER crop rotation system (Prestations Écologiques Requises, required ecological benefits) evolves even further by integrating an agroecological and agroforestry complex.

This set of best practices promotes the presence of auxiliaries that will themselves protect the soil and crops.

Some examples of auxiliaries:

- Mushrooms, to rapidly degrade organic matter

- The earthworm structures the soil

- The carabidae beetle against slugs

- Bees pollinate plants

- Bats feed on nocturnal insects

- The kestrel falcon hunts rodents

In order to ensure the need for local cereals for our hens, we work with farmers in Chablais who meet the following requirements:

- PER crop rotation (Prestations Écologiques Requises, required ecological benefits)

- Agroecological practice

- Member of a CQP network (Contributions to Landscape Quality)

Our local collaborators:

- Moulin du Chêne SA, Les Evouettes

- Jean-Pierre Mandrin, Aigle

- Séchoir de Vouvry

Mill and oil mill

Artisanally prepared in our mill and oil factory, the chicken feed is always fresh and 100% vegetable. Corn, wheat, protein peas, soybeans and alfalfa come from our farm and our employees in Chablais, according to our specifications.

Outdoor breeding PER, SST and SRPA

Our hens meet all PER requirements. From their first breath, they frolic in freedom and have at their disposal a TMS (stabulation system particularly respectful of animals) and SRPA (Sorties Régulières Plein Air, regular outdoors outings).

We fight pests via means of purely biological and biodegradable processes.

Quality control and conditioning

Every day, our eggs are transported from the chicken coops directly to the quality control area. The eggs are then checked, mirrored, calibrated, marked and packaged on a machine managed by state-of-the-art technologies.

Electric delivery

Our delivery service is equipped with all-electric vehicles. The batteries are recharged with renewable energy. We guarantee freshness by the shortest path to benefit the consumer and the environment.